In today’s rapidly evolving pharmaceutical industry, efficient storage and logistics systems are crucial for maintaining the integrity of products and ensuring timely delivery. One innovative solution that has gained significant traction is pharmaceutical automated storage. This article will explore the benefits of this technology and discuss different models and categories available in the market.

HWArobotics: Revolutionizing Pharmaceutical Warehousing

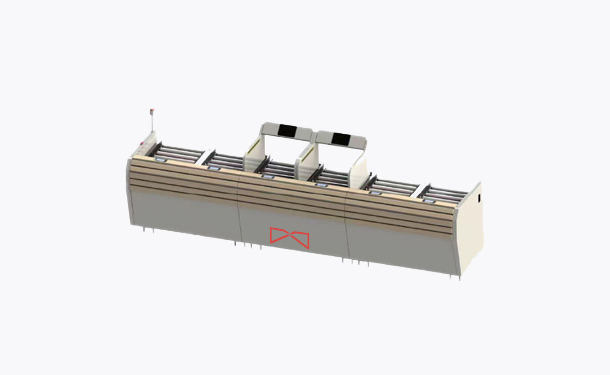

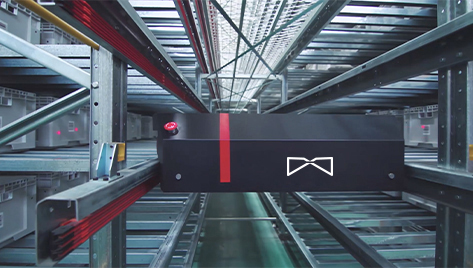

The modern logistics center of Sichuan Kelun Medicine & Trade serves as a prime example of how HWArobotics‘ multi-level AS/RS shuttle system has transformed pharma warehousing. With 78 SLS320 standard case-handling shuttles managing over 33,000 storage units in a 6-aisle AS/RS, this advanced system enables goods-to-person automatic split picking with an impressive compound throughput of up to 6,000 bins per hour.

To complement their automated storage solution, the pharmaceutical warehousing logistics center also incorporates state-of-the-art facilities such as PGC500 modular conveyors, PSD310 double-layer sorters, flow racks, shelf racks, RFID technology, inspecting and packing stations, automatic labeling machines, spiral lifts, and high-speed sorters. These integrated components work together seamlessly to optimize efficiency throughout the entire supply chain process.

Different Models for Pharmaceutical Automated Storage

When it comes to pharmaceutical automated storage systems (AS/RS), there are several models available on the market:

Vertical Lift Modules (VLMs): This model utilizes vertical space efficiently by storing items in enclosed columns with trays or shelves that can be automatically retrieved using robotic mechanisms. VLMs offer high-density storage while minimizing floor space requirements.

Horizontal Carousels: A horizontal carousel system consists of a series of bins or shelves that rotate horizontally on an oval track. This model provides quick access to stored items and is suitable for high-speed order picking.

Vertical Carousels: Similar to horizontal carousels, vertical carousels consist of rotating shelves. However, in this model, the shelves move vertically instead of horizontally. Vertical carousels are ideal for storing small parts and components.

Automated Storage and Retrieval Systems (AS/RS): This comprehensive solution combines various technologies such as shuttles, conveyors, sorters, and robotic arms to automate the storage and retrieval process. AS/RS systems offer high throughput rates with minimal human intervention.

The Future of Pharmaceutical Automated Storage

In conclusion, pharmaceutical automated storage has revolutionized the way warehouses operate in the pharmaceutical industry. By implementing advanced technologies like those offered by HWArobotics’ multi-level AS/RS shuttle system, companies can significantly improve efficiency while maintaining product integrity throughout the supply chain process. As technology continues to advance rapidly in this field, we can expect even more innovative solutions that will further optimize pharmaceutical warehousing operations.